News

All About Acrylic Sheets: Properties, Advantages, Disadvantages, and Classifications

All About Acrylic Sheets: Properties, Advantages, Disadvantages, and Classifications

Acrylic sheets, also known as plexiglass or PMMA sheets, are a type of synthetic plastic made from methyl methacrylate (MMA). First developed in the 1930s, they are now produced by many renowned brands such as PS (Japan), Fu Sheng (Taiwan), and SH (China). Featuring a smooth surface that can be transparent or available in a wide range of colors, acrylic sheets are widely used in advertising, interior design, and as an alternative to traditional glass thanks to their lightweight nature, durability, and ease of fabrication.

1. Classification of Acrylic Sheets

However, to be more precise, we need to distinguish between two concepts: natural mica and synthetic acrylic (PMMA) mica.

Natural mica is a type of mineral with a sheet-like structure, known for its excellent electrical insulation and heat resistance. There are several types of natural mica, such as muscovite, biotite, and phlogopite. However, it is rarely used in industrial applications due to limitations in purity and sheet size.

Synthetic mica (Acrylic, PMMA) is the most commonly used type today. It is made from acrylic plastic (Poly Methyl Methacrylate) and is characterized by its transparency, durability, light weight, and ease of fabrication.

2. Acrylic Sheet Specifications

Below is the current technical specification table for acrylic sheets:

|

|

|

|

Standard Size |

1.22m × 2.44m (can be cut to custom sizes) |

|

Thickness |

Range from 1mm to 50mm. Common thicknesses include 2mm, 3mm, 5mm, 8mm, 10mm, 15mm, and 20mm. |

|

Density |

|

|

|

|

|

|

|

|

|

|

|

|

|

3. Key Features of Acrylic Sheets

Acrylic sheets are increasingly used in various industries thanks to the following standout characteristics:

- High Transparency: Acrylic can transmit up to 92% of light, offering an effect similar to glass but with much greater safety.

- Lightweight: Considerably lighter than traditional glass, helping reduce installation pressure and lowering transportation costs.

- High Durability: Approximately 10 times stronger than ordinary glass, highly resistant to impact, and less likely to crack or shatter during use.

- Easy Fabrication and Shaping: Can be easily cut, bent, drilled, or CNC-engraved into various shapes without surface cracking, making it widely applicable in industrial manufacturing.

- UV Resistance: Protects against ultraviolet rays, helping acrylic retain its color and clarity even after prolonged exposure to sunlight.

- Variety in Colors and Thicknesses: Available in options ranging from transparent and translucent to vibrant solid colors, meeting diverse needs for interior design and specific applications.

- High Aesthetic Appeal: With a smooth, glossy surface, acrylic offers a modern, refined appearance. It is also easy to clean and maintain its like-new look throughout its lifespan.

Drawbacks of Acrylic Sheets

- Prone to Scratches: One of its main weaknesses—its relatively soft surface can be scratched by sharp objects or when cleaned with abrasive materials.

- Limited Heat Resistance: Typically withstands temperatures up to around 80°C; exceeding this limit can cause deformation, bubbling, and loss of original aesthetics.

- Brittleness Under Heavy Impact: Although more impact-resistant than glass, acrylic can still be brittle and crack into large pieces if subjected to strong, concentrated force.

- Outdoor Aging: Low-quality or uncoated acrylic may yellow, lose clarity, and become more brittle after prolonged exposure to sunlight and harsh weather conditions.

4. Common Types of Acrylic Sheets

Nowadays, acrylic sheets on the market are highly diverse and are categorized into different groups based on specific criteria.

By Origin

Depending on the manufacturer and quality standards, acrylic sheets are divided into

Taiwanese Acrylic

Chinese Acrylic

Japanese Acrylic

By Color and Effect

-

Transparent Acrylic: Offers high light transmission, often used as a glass substitute thanks to its light weight, high safety, and ease of fabrication.

- Frosted Acrylic: Features a matte surface that limits visibility, ideal for office partitions, bathrooms, or spaces requiring privacy.

- Colored Acrylic: Available in hundreds of shades from light to dark, meeting diverse requirements for interior design, advertising, and displays.

- Mirror Acrylic: Has a reflective surface similar to real mirrors, commonly used in decoration, signage, or to create a sense of spatial depth.

- Light-Diffusing / Illuminated Acrylic: Capable of dispersing or emitting light, applied in lightboxes, signage, and artistic lighting designs.

By Thickness

Depending on the intended use, acrylic sheets are manufactured in various thicknesses, most commonly:

- 1mm – 3mm: Suitable for small decorative details, printing, nameplates, etc.

- 5mm – 10mm: Ideal for signage, lightboxes, and display stands.

- Over 50mm: Used for applications requiring high rigidity such as partitions, display tanks, or light-load structural components.

With many advantages such as high transparency, good durability, light weight, and ease of fabrication, acrylic (PMMA) is increasingly popular across multiple fields, from advertising and interior design to industrial applications. While it has certain limitations—such as being prone to scratches and having low heat resistance—choosing the right type of acrylic for the intended purpose makes it an effective and economical material.

Understanding its properties, classifications, and applications will help you make the right decision when selecting acrylic for your construction and design projects.

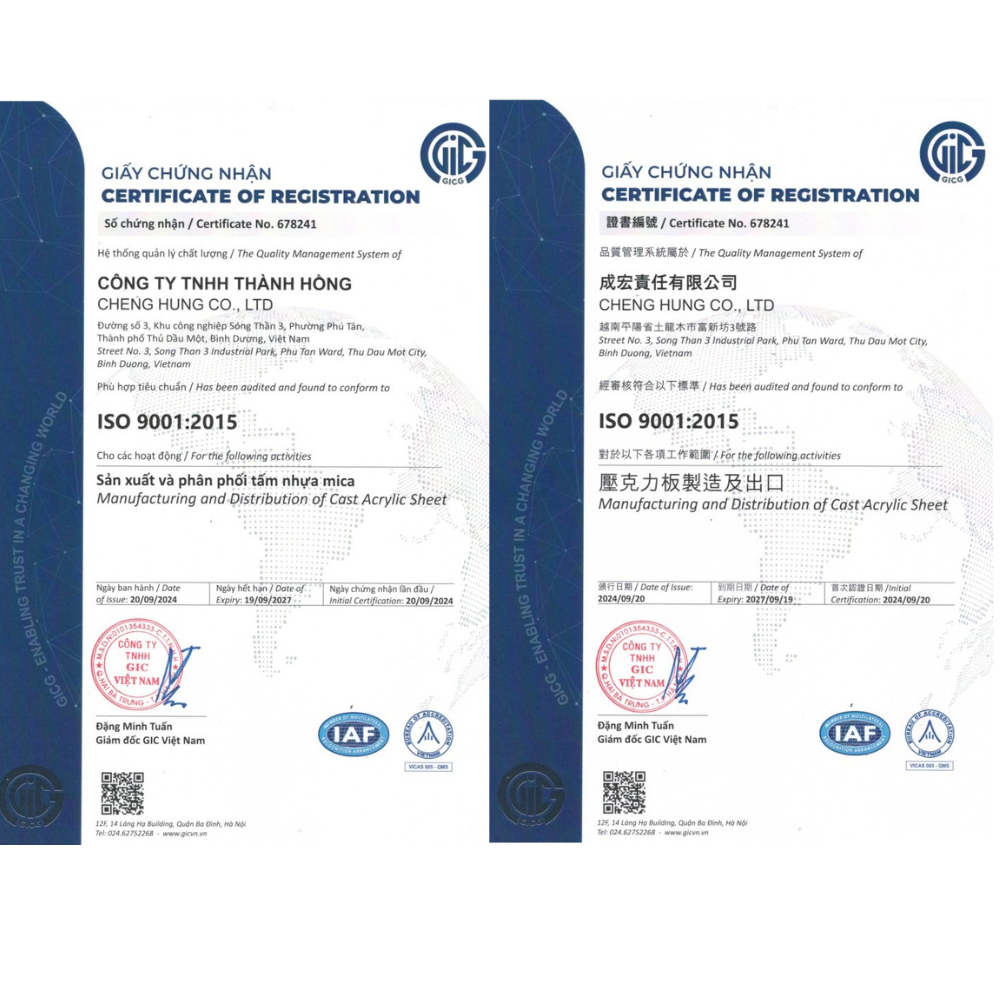

THÀNH HỒNG CO., LTD – Specializing in High-Quality Acrylic Sheet Manufacturing

Address: Street No. 3, Song Than 3 Industrial Park, Phu Tan Ward, Thu Dau Mot City, Binh Duong Province, Vietnam

Website: https://thacrylics.com/vn/

Hotline:

-

International Calls: +84 274 376 4298

-

Domestic Calls: 0274 366 9918

Mail: info@thacrylics.com

Readers comments

Nowadays, acrylic sheets on the market are highly diverse and are categorized into different groups based on specific criteria.

By Origin

Depending on the manufacturer and quality standards, acrylic sheets are divided into

|

Taiwanese Acrylic |

|

|

Chinese Acrylic |

|

|

Japanese Acrylic |

|

By Color and Effect

-

Transparent Acrylic: Offers high light transmission, often used as a glass substitute thanks to its light weight, high safety, and ease of fabrication.

- Frosted Acrylic: Features a matte surface that limits visibility, ideal for office partitions, bathrooms, or spaces requiring privacy.

- Colored Acrylic: Available in hundreds of shades from light to dark, meeting diverse requirements for interior design, advertising, and displays.

- Mirror Acrylic: Has a reflective surface similar to real mirrors, commonly used in decoration, signage, or to create a sense of spatial depth.

- Light-Diffusing / Illuminated Acrylic: Capable of dispersing or emitting light, applied in lightboxes, signage, and artistic lighting designs.

By Thickness

Depending on the intended use, acrylic sheets are manufactured in various thicknesses, most commonly:

- 1mm – 3mm: Suitable for small decorative details, printing, nameplates, etc.

- 5mm – 10mm: Ideal for signage, lightboxes, and display stands.

- Over 50mm: Used for applications requiring high rigidity such as partitions, display tanks, or light-load structural components.

With many advantages such as high transparency, good durability, light weight, and ease of fabrication, acrylic (PMMA) is increasingly popular across multiple fields, from advertising and interior design to industrial applications. While it has certain limitations—such as being prone to scratches and having low heat resistance—choosing the right type of acrylic for the intended purpose makes it an effective and economical material.

Understanding its properties, classifications, and applications will help you make the right decision when selecting acrylic for your construction and design projects.

THÀNH HỒNG CO., LTD – Specializing in High-Quality Acrylic Sheet Manufacturing

Address: Street No. 3, Song Than 3 Industrial Park, Phu Tan Ward, Thu Dau Mot City, Binh Duong Province, Vietnam

Website: https://thacrylics.com/vn/

Hotline:

-

International Calls: +84 274 376 4298

-

Domestic Calls: 0274 366 9918

Mail: info@thacrylics.com

Readers comments

-

Transparent Acrylic: Offers high light transmission, often used as a glass substitute thanks to its light weight, high safety, and ease of fabrication.

- Frosted Acrylic: Features a matte surface that limits visibility, ideal for office partitions, bathrooms, or spaces requiring privacy.

- Colored Acrylic: Available in hundreds of shades from light to dark, meeting diverse requirements for interior design, advertising, and displays.

- Mirror Acrylic: Has a reflective surface similar to real mirrors, commonly used in decoration, signage, or to create a sense of spatial depth.

- Light-Diffusing / Illuminated Acrylic: Capable of dispersing or emitting light, applied in lightboxes, signage, and artistic lighting designs.

By Thickness

Depending on the intended use, acrylic sheets are manufactured in various thicknesses, most commonly:

- 1mm – 3mm: Suitable for small decorative details, printing, nameplates, etc.

- 5mm – 10mm: Ideal for signage, lightboxes, and display stands.

- Over 50mm: Used for applications requiring high rigidity such as partitions, display tanks, or light-load structural components.

With many advantages such as high transparency, good durability, light weight, and ease of fabrication, acrylic (PMMA) is increasingly popular across multiple fields, from advertising and interior design to industrial applications. While it has certain limitations—such as being prone to scratches and having low heat resistance—choosing the right type of acrylic for the intended purpose makes it an effective and economical material.

Understanding its properties, classifications, and applications will help you make the right decision when selecting acrylic for your construction and design projects.

THÀNH HỒNG CO., LTD – Specializing in High-Quality Acrylic Sheet Manufacturing

Address: Street No. 3, Song Than 3 Industrial Park, Phu Tan Ward, Thu Dau Mot City, Binh Duong Province, Vietnam

Website: https://thacrylics.com/vn/

Hotline:

-

International Calls: +84 274 376 4298

-

Domestic Calls: 0274 366 9918

Mail: info@thacrylics.com