News

Differences Between Extruded Acrylic and Cast Acrylic

Differences Between Extruded Acrylic and Cast Acrylic

When choosing acrylic sheets for advertising, interior design, or industrial applications, users often come across two main types: extruded acrylic and cast acrylic. Although both are made from acrylic (PMMA), their manufacturing processes and physical properties differ significantly. Let’s explore these differences in detail to help you select the right product for your needs.

1. What is Extruded Acrylic?

Extruded acrylic is a method in which acrylic sheets are produced from MMA material in liquid form. In the Vietnamese market, Taiwanese acrylic represents this production method.

To produce acrylic sheets, the manufacturer uses a glass mold made of two special tempered glass panels stacked together, with the gap between them equal to the desired sheet thickness. A rubber strip is pressed around the perimeter of the glass panels to create a sealed space between them. The liquid MMA is poured into the space between the glass panels and immersed in a special solution, allowing the MMA to naturally condense and solidify. The immersion time depends on the sheet’s thickness.

With this method, acrylic sheets achieve high transparency and excellent chemical resistance, as the MMA compound solidifies naturally.

However, the biggest drawback of this method is that the sheet thickness may vary across different areas of the surface due to uneven material shrinkage.

Characteristics of Extruded Acrylic:

- Highly uniform thickness thanks to the continuous extrusion process.

- Flat, smooth surface but more prone to scratches compared to cast acrylic.

- Lower production cost, suitable for mass production.

- Easy to bend, cut, print, and process with CNC or laser machines.

Common Applications:

- Advertising signs and 3D acrylic letters.

- LED lightboxes, electrical cabinets, and partitions.

- Product packaging, display trays.

2. What is Cast Acrylic?

The raw materials used to produce acrylic sheets with this technology are PMMA, MS, and PS resin pellets. In the Vietnamese market, Malaysian and Chinese acrylic represent this manufacturing method.

The resin pellets pass through a heating system to soften, then through rollers to be flattened into acrylic sheets of the required thickness. With this method, the length of the acrylic sheet can be customized as desired.

The advantage of this method is that the sheet thickness is uniform across the entire surface. However, the drawback lies in the limitations of the materials used. Acrylic sheets made from PMMA, MS, and PS resin pellets generally have lower chemical resistance, and their quality depends on the material’s properties.

Characteristics of Cast Acrylic:

- Higher transparency, gloss, and durability.

- Slight thickness variation possible (±10%).

- Better impact and heat resistance than extruded acrylic.

- Allows for more precise fabrication, suitable for products requiring high accuracy.

Common Applications:

- Premium gift boxes and luxury display stands.

- Medical equipment, tabletops, and faux glass doors.

3. Should You Choose Extruded or Cast Acrylic?

- If you need mass production, cost efficiency, and quick turnaround time, choose extruded acrylic.

- If you need high quality, excellent transparency, long-lasting durability—especially for display products or applications with strict aesthetic requirements—choose cast acrylic.

Each type of acrylic has its own advantages and is suitable for different purposes. Understanding the production process and technical properties of both extruded and cast acrylic will help you select the right product, save costs, and still ensure quality and efficiency in your work.

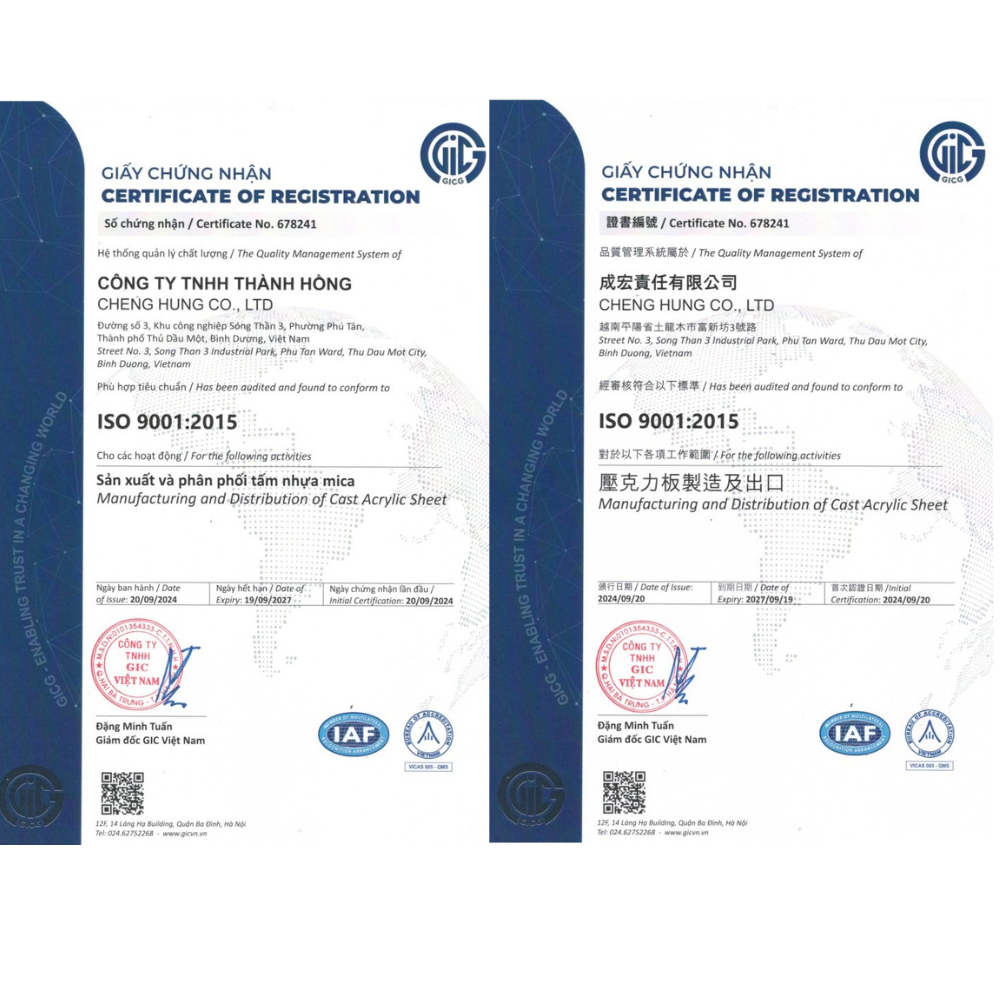

THÀNH HỒNG CO., LTD – Specializing in High-Quality Acrylic Sheet Manufacturing

Address: Street No. 3, Song Than 3 Industrial Park, Phu Tan Ward, Thu Dau Mot City, Binh Duong Province, Vietnam

Website: https://thacrylics.com/vn/

Hotline:

- International Calls: +84 274 376 4298

- Domestic Calls: 0274 366 9918

Email: info@thacrylics.com